|

|

Products- Hydraulic Power Units |

|

Electric/Hydraulic Power Sources |

|

|

|

|

DEDICATED POWER UNITS are

used when:

|

|

|

Picture shows a DEDICATED POWER UNIT (right) in a vault at a water treatment plant in California. At left is the Kanair quarter-turn modulating servo actuator mounted on a 78" butterfly valve (only the spool extension of the valve is seen). Some features:

System designed for continuous modulating controls. |

|

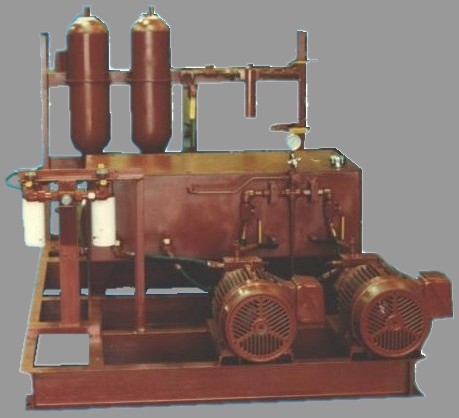

Picture shows a DEDICATED POWER UNIT for use in a Power Plant in Houston. The Power Unit modulated a louver/damper actuator on 4-20 mA command from control room. The damper controlled airflow to furnace of a 600 megawatt. In order to increase the reliability of the system (in fly ash environment), motors, accumulators, filters etc., was duplicated. The system was designed to function without failure for 18 months. Two custom designed Power Units and associated Two Electro hydraulic Servo Actuators were delivered to the customer in 12 days. System functioned without failure for 18 months as required with a several fold return on investment. |

|

Picture shows a DEDICATED POWER UNIT (left) and a Spring Return Actuator mounted on a 36" Butterfly Valve (right). The Energy Source is High Pressure Air stored at 2200 psig in gas bottles. Two air over oil tanks convert the pneumatic energy to hydraulic type for smooth operation of the fail close actuator when an earthquake sensor is triggered on severe earthquake conditions. |